In our laboratory, we carry out cleanliness determinations and analyses of function-relevant components in compliance with VDA 19 and ISO 16232 or according to our company standards for medical technology, automotive industry and component supply industry, hydraulics applications, precision engineering and other industrial sectors. We use our own systems to perform inspections of technical cleanliness. Many years of experience gained by providing advice to our customers enable us to constantly optimise our systems. Gravimetric analysis:

A well-trained staff and an optimum room environment are essential to ensure that the analyses meet all your requirements. Please feel free to contact us for an offer. We can provide you with a solution tailored to suit your specific needs.

All extraction processes can be carried out at our premises. We use our own systems to perform the extraction processes spraying, ultrasound, rinsing and shaking. The system cleanliness is constantly monitored by means of blank values.

To determine the weight portions of a test object, we use an analytical balance by Kern, providing an accuracy of 0.01 mg and automatic calibration.

Gravimetric analysis provides information on the total mass of the particle load, but not on the size distribution of the particles on the analysis filter.

Precise weighing requires careful preparation and drying of the analysis filter in the drying oven, followed by recooling in a desiccator.

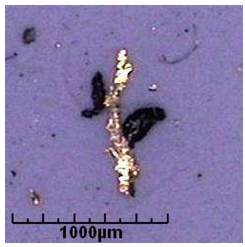

Light microscopy (LM) and scanning electron microscopy (SEM) are suitable methods for evaluation of filter membranes in terms of particle load. The particles separated in the filtration process can be measured and counted. The use of optical microscopes or scanning electron microscopes depends on the requirement. The analysis provides the number and size of the particles detected on the analysis filter - the particle size distribution. As the function of components may be affected even by single or less critical particles, it is necessary to analyse the entire filter surface.

For light microscopy, we use a computer-controlled system from Jomesa, featuring automatic counting and measuring of particles on the filter membrane. This microscopy method thus provides accurate and reproducible results. The automatic analysis distinguishes between metallic and non-metallic particles.

In the field of scanning electron microscopy, Brändle GmbH cooperates with other institutes.